Key Takeaways

- Pogo pins provide reliable, spring-loaded electrical connections ideal for testing, charging, and data transfer without permanent soldering.

- These connectors are widely used in applications like PCB test jigs, consumer electronics, medical devices, and aerospace equipment.

- Proper selection, clean handling, and precise alignment are crucial for ensuring stable and repeatable pogo pin connections.

- Regular maintenance, such as cleaning contact surfaces and inspecting for wear, extends pogo pin lifespan and optimizes performance.

- Troubleshooting common issues—like misalignment, contamination, or spring fatigue—prevents connection failures and ensures quality results.

Pogo pins are spring-loaded connectors that create temporary electrical connections for testing, charging, and data transfer without requiring permanent soldering. These versatile components are widely used across consumer electronics, medical devices, and aerospace applications, offering flexibility and efficiency in electronic design. Understanding proper usage techniques prevents common connection issues and ensures reliable performance. Leading pogo pin manufacturer companies provide customised solutions for diverse industrial requirements.

What Are Pogo Pins?

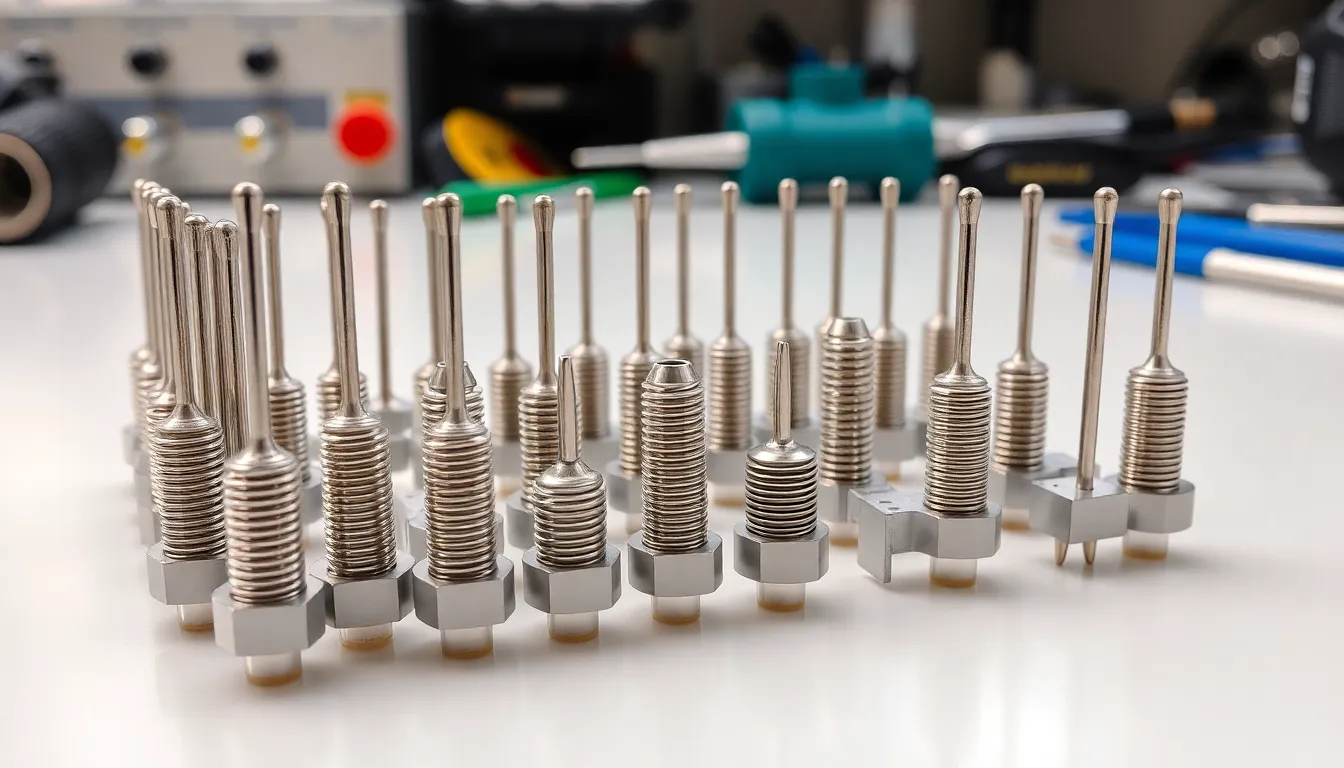

Pogo pins are precision-engineered, spring-loaded connectors that create temporary electrical contact between electronic circuits. Manufacturers use these pins for applications needing reliable, repeatable connections where fast assembly or automated testing is required. Key industries using pogo pins include consumer electronics, aerospace, and medical device sectors.

Each pogo pin consists of three main parts: a barrel, a plunger, and an internal spring. The plunger extends from the barrel and compresses when pressed against a mating pad, maintaining stable contact through controlled spring force. This design reduces wear on both connectors and PCBs.

Promax in China manufactures pogo pins in different geometries, including single and dual-ended pins, shielded pins for RF applications, and magnetic connector assemblies for faster alignment. Gold plating is used on contact surfaces to guarantee low resistance and corrosion resistance in high-cycle operations.

Engineers select pogo pins for test jigs, docking stations, wearables, phones, and charging cradles. For example, PCB testing fixtures and battery connectors often use pogo pins to allow repeated connections without soldering. Promax designs pogo pin solutions for low-profile enclosures, high mating cycles, and custom current ratings, supporting high-volume production and strict quality requirements.

Common Applications of Pogo Pins

Test jigs for PCB assembly use pogo pins to create durable and repeatable electrical connections during in-circuit and functional testing. Engineers mount pogo pins in custom test fixtures, pressing them against PCB test pads for automated signal verification with hundreds of cycles per day. Promax supplies high-precision pogo pins for high-volume test stations and production lines.

Consumer electronics including smartphones, tablets, and wearables integrate pogo pins in charging docks, battery connections, and data transfer ports. Devices like fitness trackers, wireless earbuds, and handheld scanners rely on spring-loaded contacts for quick, reliable mating with cradles or charging stations. Promax produces gold-plated and magnetic pogo pin assemblies for these applications.

Medical devices, such as patient monitors, diagnostic probes, and portable imaging systems, embed pogo pins in modular components to ensure stable, low-resistance connections that withstand repeated sterilization and handling. Promax designs medical-grade pogo pins with corrosion-resistant plating and custom housings for compliance with regulatory standards.

Aerospace equipment, including avionics modules and satellite systems, specifies pogo pin connectors for temporary connections during prototyping, maintenance, or ground testing. Shielded pogo pin solutions from Promax support EMI protection and high-reliability requirements in these mission-critical environments.

Battery testing fixtures, semiconductor QA systems, and research instrumentation all benefit from pogo pins for non-permanent, low-wear contacts that support frequent mating cycles. Promax customizes pogo pin dimensions, spring forces, and barrel lengths to fit demanding electrical and mechanical parameters.

Preparing to Use Pogo Pins

Correct preparation helps engineers prevent connection errors and improve test yields when working with pogo pins in R&D or production lines. Proper component selection, handling, and workspace preparation lead to consistent performance in board-to-board and device-to-jig connections.

Selecting the Right Pogo Pins

Selecting the right pogo pins depends on project requirements, such as pitch, current rating, and stroke length. Engineers identify mechanical space constraints and contact locations before choosing barrel diameter, pin length, and plunger tip geometry. For applications needing strong signal integrity, shielded pogo pins from Promax provide enhanced EMI protection. Gold plating ensures low contact resistance in medical, aerospace, and consumer electronics. Custom configurations offer options like magnetic guidance, double-ended designs, or solder cup terminations for unique test setups. Consulting manufacturer datasheets from Promax enables matching pin ratings with projected current and mating cycle demands.

Safety Considerations

Handling pogo pins safely prevents failures and workplace injuries. Staff use antistatic tools and ESD-safe mats to reduce static discharge, which could damage sensitive spring-loaded connectors during installation or testing. Wearing clean gloves keeps oils and moisture from contaminating gold-plated pins, preserving conductivity in rigorous QA environments. Magnets and sharp-tipped pogo pins require careful handling to avoid pinching or puncture hazards. Secure fixtures and clear labeling ensure operators correctly align connectors with PCB pads. Promax supplies detailed material safety data and offers guidance on best practices for safe assembly procedures in mass production and laboratory setups.

Step-By-Step Guide on How to Use Pogo Pins

Pogo pins enable efficient assembly and testing for electronic devices by ensuring stable, repeatable contact. Follow these steps to set up and validate pogo pin connections for high-volume production or prototyping.

Setting Up the Connection

Begin setup by selecting pogo pins that match the application’s pitch, stroke length, and current rating. Clean the work surface and components with ESD-safe brushes and ensure all pins from suppliers like Promax are free from contamination or physical defects. Insert pogo pins into the fixture using supporting tools—such as insertion jigs—for uniformity. Secure the mounting by pressing pins fully into their designated housings or sockets until resistance is felt. Confirm all pins are vertically oriented and seated flush, as angled or loose pins can disrupt contact reliability.

Ensuring Proper Alignment

Align the device under test (DUT) with the pogo pin fixture using built-in mechanical guides, which may include dowels or notches provided by Promax’s custom test solutions. Position the DUT slowly above the spring-loaded array, ensuring all target pads match pin locations. Monitor the process visually, verifying each pad contacts its corresponding pin. Apply even, moderate pressure to avoid bending or dislodging the pins. Lock the DUT in place using fixture clamps or magnetic retention if required by the design.

Testing the Electrical Contact

Begin the test procedure by connecting the assembly to a power or signal source. Activate the relevant power supply and measurement equipment—such as a continuity tester or digital multimeter—to assess electrical paths. Observe test status indicators, checking for stable, low-resistance readings across each pin. Address any open or high-resistance results by reseating the DUT or reinspecting pin seating. Promax’s pogo pin assemblies support repeated test cycles, making it essential to verify results after multiple insertions to confirm ongoing contact reliability.

Tips for Effective Use of Pogo Pins

- Maintain Clean Contact Surfaces

Clean pogo pin tips and device pads before use to prevent connection resistance. Dust and oxidation on gold plating reduce signal quality and increase wear.

- Check Alignment and Pitch Accuracy

Align pogo pin arrays with device pads to avoid bent pins and signal loss. Use precision jigs or fiducial markers for arrays larger than 10 pins with 0.5 mm pitch.

- Apply Controlled Insertion Force

Use even pressure when engaging pogo pins so the internal spring remains compressed within specified limits. Over-compression of pins rated by Promax for 2.5 mm maximum stroke causes premature fatigue.

- Regularly Inspect for Wear or Damage

Inspect pogo pins for bent barrels and worn tips after 1,000 insertion cycles. Replace pins if gold plating wears through; Promax recommends replacement to maintain stable electrical contact.

- Store Pins in Antistatic Environments

Store unused pogo pins in ESD-safe trays at 20–25°C with relative humidity under 65%. Electrostatic discharge or excess moisture oxidizes springs and barrels, leading to contact failure.

- Use Recommended Accessories from Manufacturers

Source compatible sockets, custom housings, and centering fixtures from providers like Promax to guarantee reliable mating and signal integrity in production test jigs.

- Follow Manufacturer’s Cleaning and Handling Guidelines

Adhere to Promax’s documented cleaning methods, which specify lint-free swabs and isopropyl alcohol for gold contacts. Avoid using abrasive materials to extend pin life.

Troubleshooting Common Issues

Connection problems often occur when pogo pins lose contact with test pads, increasing signal resistance or causing erratic readings. Dirt or oxidation on the tips of pogo pins or pads leads to unreliable electrical contact. Prompt cleaning with alcohol or a soft antistatic brush restores performance.

Alignment errors may bend pins, especially in fine-pitch test jigs where tolerance is minimal. Checking pin position before pressing down and verifying fixture alignment prevents this damage. For assemblies using Promax pogo pin arrays, design fixtures with precise guides to maintain proper pin-to-pad contact.

Spring fatigue emerges after repeated cycles, especially above 100,000 actuations for standard pogo pins. If engineers notice weakened spring force or intermittent connections, replacing worn pins resolves the failure. Promax offers replacement pogo pins compatible with most standard and custom fixtures.

Electrical shorts happen when pin barrels touch adjacent conductors due to improper spacing or fixture shift. Using pin geometries from Promax with insulated or shielded housings reduces short risk in high-density arrays.

Breakage during insertion results from excessive force or mishandling. Training operators to use controlled force and following Promax’s handling procedures helps prevent premature pin failure.

Testing contact resistance with a digital multimeter identifies issues—stable readings confirm good contact while fluctuating values indicate contamination or pin fatigue. Using this method ensures reliable pogo pin performance in electronics production and quality assurance.

About Promax Pogo Pin

Promax Pogo Pin specializes in manufacturing high-quality pogo pins, spring-loaded connectors, and magnetic connectors for consumer electronics, aerospace, and medical industries. With over 15 years of expertise, they provide customizable solutions, competitive pricing, and internationally certified quality standards. Whether it’s a standard connector or a custom design, they are equipped to deliver precision-engineered solutions for diverse applications.

Contact:

Gavin Yi, Director

Phone: (765) 705-7361

Email: [email protected]

Website: promaxpogopin.com

Location: 480 Jackson St, Gary, IN 46402, USA

Frequently Asked Questions

What are pogo pins?

Pogo pins are small, spring-loaded connectors designed to create temporary electrical contact. They enable quick, reliable connections in electronic devices without requiring soldering, commonly used for testing, charging, and data transfer.

Where are pogo pins commonly used?

Pogo pins are widely used in consumer electronics, medical devices, aerospace, test jigs, battery testing fixtures, and semiconductor QA systems due to their flexibility and reliable connections.

What are the main components of a pogo pin?

A pogo pin typically consists of a barrel, a plunger, and an internal spring. This structure helps maintain stable and repeatable electrical contact with minimal wear on both the pin and mating surfaces.

How do pogo pins improve prototyping and testing?

Pogo pins allow fast, solder-free connections, making them ideal for prototyping and custom test fixtures. They help engineers streamline assembly, solderless testing, and frequent device swaps while ensuring reliable contact.

How should I select the right pogo pin for my project?

Choose pogo pins based on current rating, pitch (spacing), stroke length, and application requirements. Consider the material, spring force, and any special features like magnetic or shielded versions.

What preparation is needed before using pogo pins?

Make sure to select appropriate pins, set up a clean workspace, and use antistatic tools. Proper handling and correct alignment of the device under test help prevent connection errors and improve yields.

How do I maintain pogo pin connectors?

Keep contact surfaces clean, regularly inspect for wear, store pins in antistatic containers, and follow manufacturer cleaning and handling guidelines to prevent oxidation and prolong their lifespan.

What common issues can occur with pogo pins?

Common issues include poor connections from dirt or oxidation, misalignment causing bent pins, and loss of spring force after repeated use. Regular cleaning and careful handling help prevent these problems.

How do I test if pogo pins are making good contact?

Use a continuity tester or digital multimeter to check for stable electrical contact. Test contact resistance to ensure the connection is reliable before starting assembly or device testing.

Who manufactures customizable pogo pins?

Promax, based in China, is a leading manufacturer offering a wide range of pogo pins, including shielded and magnetic options with different geometries, gold plating, and custom dimensions for various applications.